AUXILIARY EQUIPMENT

Get a tailored budget for your project

Conditioning systems for harvested grain

The quality of the grains never improves during storage, but by means of good storage practices, it is possible to reduce quality losses to minimum levels, as well as guarantee their safety, care for the environment and protect workers’ health.

A good grain storage will depend on many factors, such as humidity and temperature of the grain, presence of insects, fungi, rodents, proper grain management, warehouse management and the equipment used by the farmer during harvest. Therefore, in order to minimize grain losses due to quality losses, Silomasters, based on its extensive experience in post-harvest practices, offers the following additional equipment with its silos.

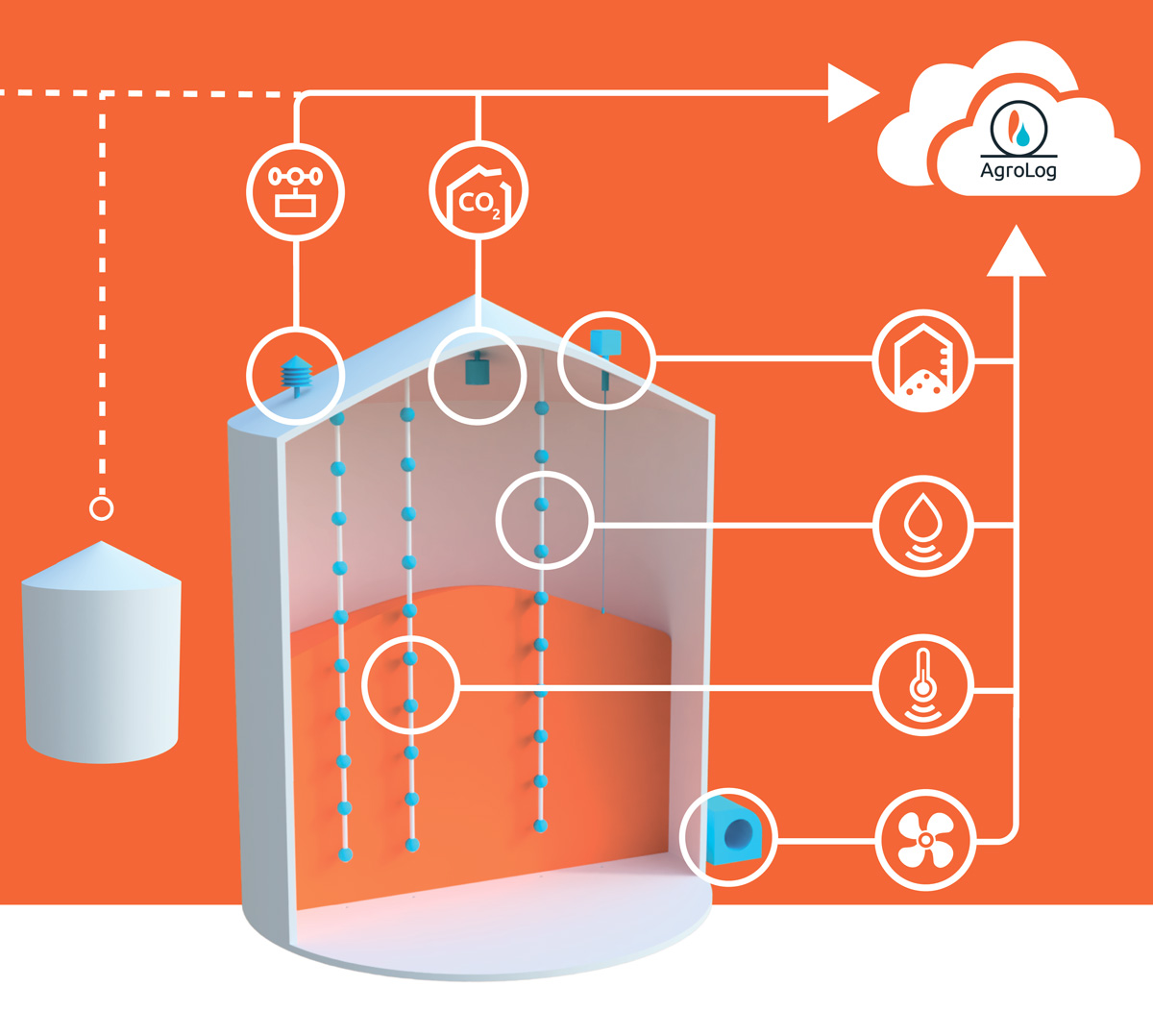

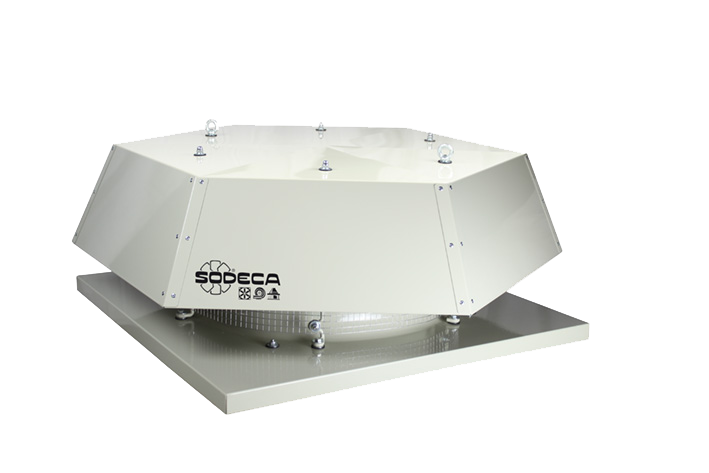

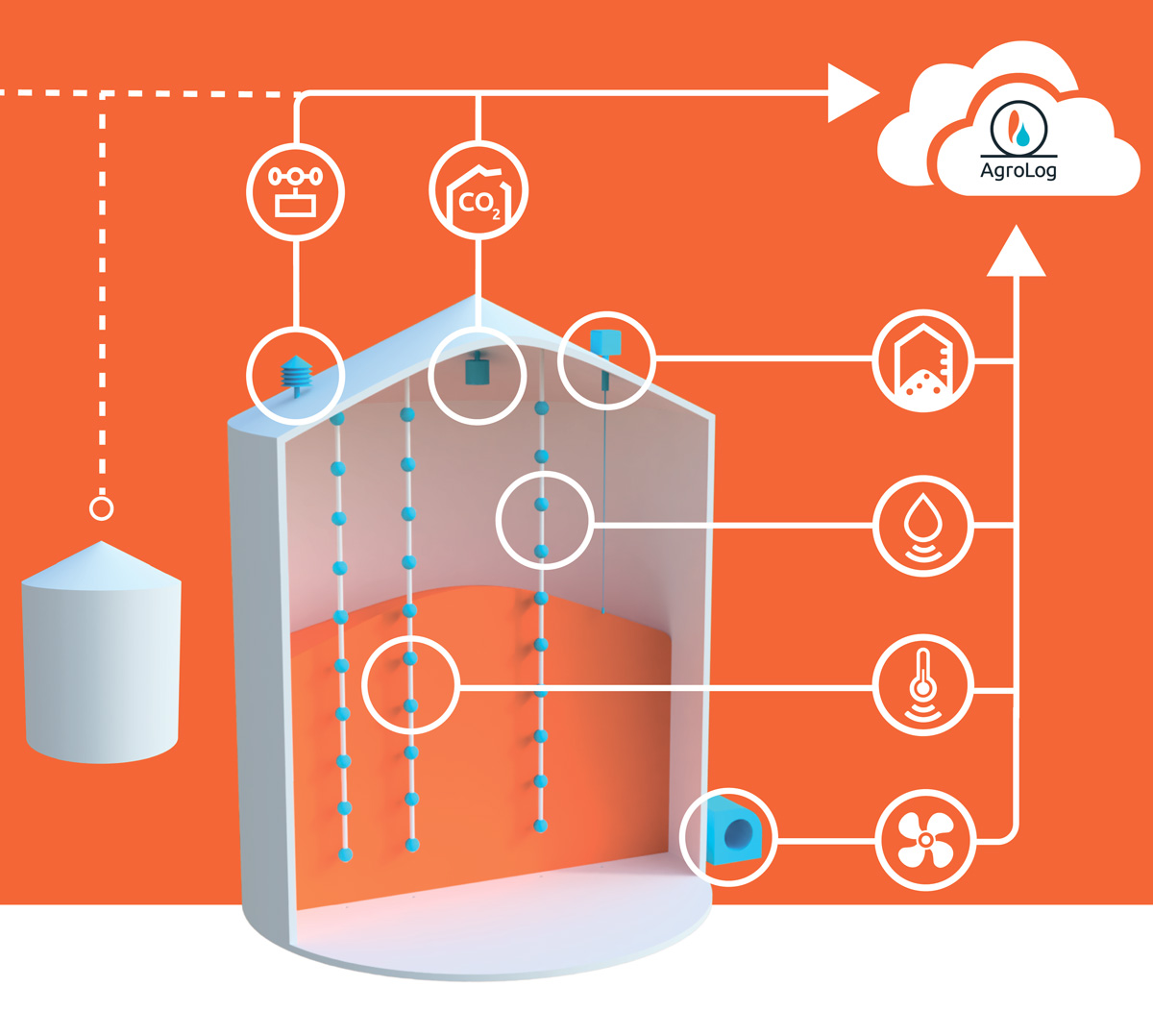

Aeration Systems

Thermometry System

To detect potential problems in the grain during storage, grain conditions should be monitored periodically.

Proper monitoring of temperature and control of potential insect activity will allow for quick and effective reaction before problems get out of control.

Emptying sweepers

The sweeper is used to complete the emptying of the silo when the grain reaches its natural slope, since, at that moment, it stops leaving through the central exit.

The sweeper, which is fixed to the centre of the silo, turns and at the same time transports the grain to the central outlet, until it turns completely.

Level Sensors

Contact us

SILOMASTER S.L.U.

Av. Alcalde Gómez Laguna 25, Floor 9-A2

50009 Zaragoza - SPAIN

Tel. +34 976 04 88 05

info@silomasters.eu

International Sales Office

C/ Rumanía 3 – 1st floor

28224 Pozuelo de Alarcón - Madrid - SPAIN

Tel. +34 91 232 19 77

info@silomasters.eu

50009 | Zaragoza

Tel.: +34 976 04 88 05

Mail: info@silomasters.eu

All rights reserved.